In today’s interconnected world, supply chains face unprecedented challenges requiring innovative approaches to maintain competitive advantage and operational continuity across global markets.

🌍 The New Reality of Global Supply Chain Management

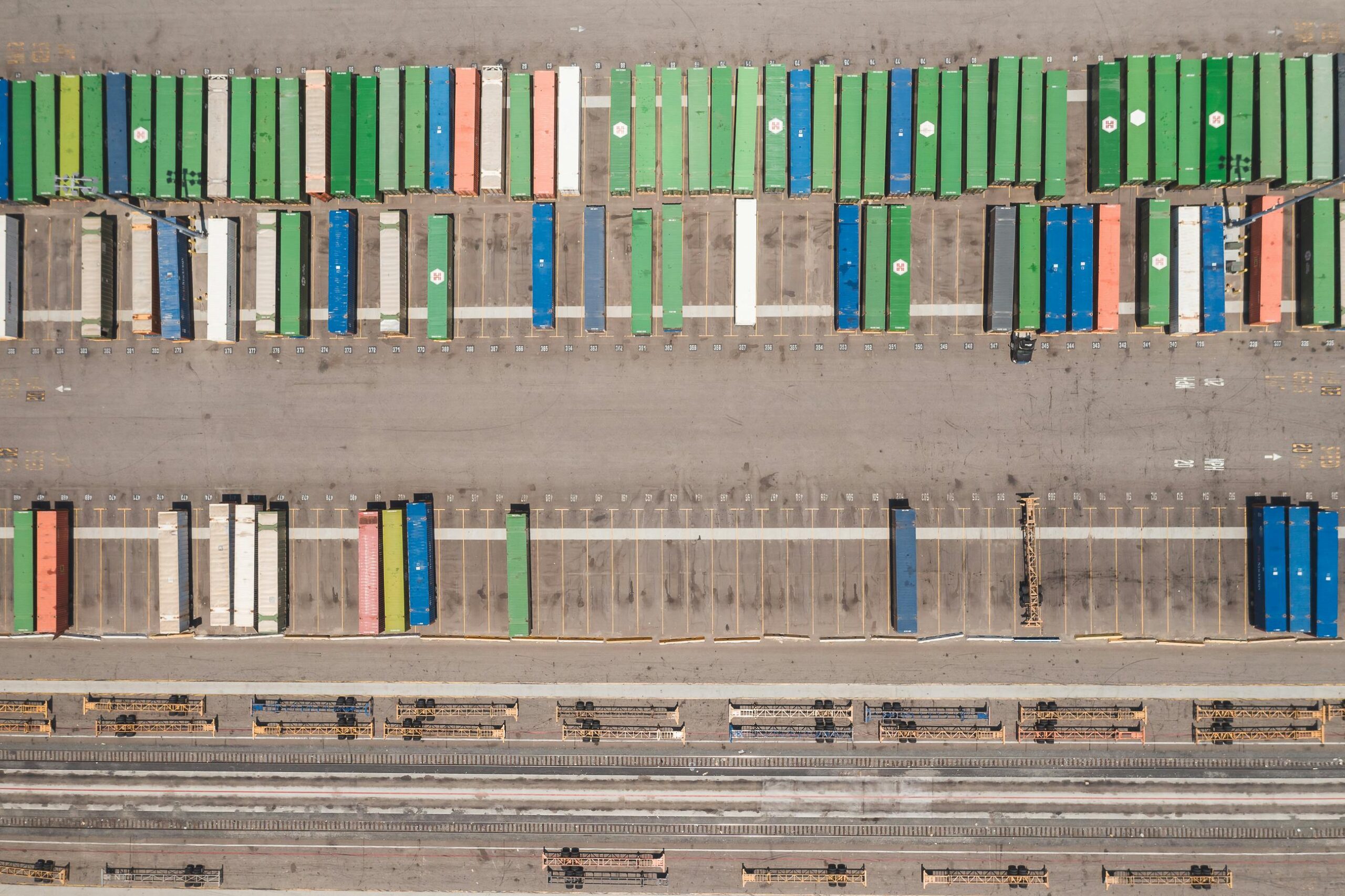

The landscape of supply chain management has transformed dramatically over the past few years. Organizations worldwide have witnessed firsthand how disruptions—whether from pandemics, natural disasters, geopolitical tensions, or technological failures—can paralyze operations within hours. This vulnerability has sparked a fundamental shift in how businesses approach supply chain strategy, moving from cost-optimization models toward resilience-focused frameworks that prioritize adaptability and sustainability.

Modern supply chains must balance multiple competing priorities simultaneously. Efficiency remains important for profitability, but resilience has become equally critical for survival. Global success now depends on building supply networks that can withstand shocks while maintaining service levels and customer satisfaction. Companies that master this balance position themselves for long-term competitive advantage in an increasingly volatile business environment.

Understanding Supply Chain Resilience in the Modern Era

Supply chain resilience refers to the ability of a network to anticipate, prepare for, respond to, and recover from disruptions while maintaining continuous business operations. This concept extends beyond simple risk management to encompass adaptive capacity and transformative capabilities that allow organizations to emerge stronger from challenges.

Resilient supply chains share several distinguishing characteristics. They maintain visibility across all tiers of suppliers and partners, enabling rapid identification of potential disruptions. They incorporate redundancy in critical areas without excessive waste. They leverage technology to enhance decision-making speed and accuracy. Most importantly, they cultivate organizational cultures that embrace agility and continuous improvement.

The Cost of Vulnerability

Organizations with fragile supply chains face substantial financial and reputational risks. Research indicates that major supply chain disruptions can reduce shareholder value by 7% on average, with effects lasting months or even years. Beyond immediate financial impact, companies suffer from customer defection, damaged brand reputation, and competitive disadvantage that compounds over time.

The automotive industry provides compelling examples of these consequences. When a fire destroyed a key semiconductor facility in 2021, multiple automakers faced production shutdowns costing billions in lost revenue. Similarly, consumer electronics companies have struggled with component shortages that delayed product launches and eroded market share to more prepared competitors.

🔧 Strategic Pillars for Building Unstoppable Supply Chains

Diversification and Risk Distribution

The “all eggs in one basket” approach has proven catastrophically inadequate for modern supply chain management. Leading organizations now embrace strategic diversification across multiple dimensions—geographic locations, supplier relationships, transportation modes, and manufacturing capabilities. This multi-sourcing strategy reduces dependency on single points of failure while creating competitive tension that drives innovation and cost improvement.

Geographic diversification involves establishing supplier and manufacturing presence across different regions to mitigate location-specific risks. Companies increasingly adopt “China plus one” or “China plus two” strategies, maintaining Chinese operations while developing alternative manufacturing bases in Southeast Asia, India, Mexico, or Eastern Europe. This approach provides flexibility to shift production based on changing conditions without complete disruption.

Supplier diversification extends beyond simply having multiple vendors for the same component. It requires developing deep relationships with suppliers at different tiers, understanding their capabilities and vulnerabilities, and creating qualification processes that enable rapid onboarding of alternative sources when needed. Forward-thinking companies invest in supplier development programs that strengthen partner capabilities and alignment with strategic objectives.

Digital Transformation and Technological Integration

Technology serves as the backbone of resilient, efficient supply chains. Advanced digital tools provide the visibility, analytics, and automation capabilities necessary to navigate complexity and respond quickly to changing conditions. Organizations that successfully integrate these technologies gain substantial competitive advantages in speed, accuracy, and adaptability.

Artificial intelligence and machine learning algorithms process vast amounts of data to identify patterns, predict disruptions, and optimize decision-making. These systems can forecast demand with greater accuracy, identify potential supplier issues before they become critical, and recommend optimal routing and inventory positioning strategies. As these technologies mature, their predictive capabilities continue improving, enabling increasingly proactive supply chain management.

Internet of Things (IoT) sensors and devices provide real-time visibility into product location, condition, and movement throughout the supply chain. This granular tracking capability enables precise inventory management, quality assurance, and exception handling. When shipments deviate from expected parameters—temperature variations for pharmaceuticals, location changes suggesting theft or misdirection, or delays indicating transportation issues—automated systems can trigger immediate responses.

Collaborative Partnerships and Ecosystem Thinking

Traditional adversarial supplier relationships based purely on price negotiation have given way to collaborative partnerships that recognize mutual interdependence and shared success. Companies building unstoppable supply chains invest in long-term relationships characterized by transparency, information sharing, and joint problem-solving.

These partnerships extend beyond dyadic relationships to encompass entire ecosystems of suppliers, customers, logistics providers, technology partners, and even competitors. Successful organizations participate in industry collaborations, sharing non-competitive information about emerging risks, best practices, and innovation opportunities. This ecosystem approach creates collective resilience that benefits all participants while strengthening individual organizational capabilities.

📊 Enhancing Operational Efficiency Without Compromising Resilience

The relationship between efficiency and resilience often appears contradictory. Traditional efficiency measures like just-in-time inventory, single-source suppliers, and minimal redundancy directly conflict with resilience principles requiring buffers, alternatives, and flexibility. However, sophisticated organizations recognize that efficiency and resilience represent complementary rather than competing objectives when properly balanced.

Intelligent Inventory Management

Modern inventory strategies move beyond simplistic just-in-time models toward more nuanced approaches that differentiate inventory based on item criticality, supply uncertainty, and demand variability. For commodity items with reliable supply and stable demand, lean inventory practices remain appropriate. However, for critical components with uncertain supply or strategic finished goods, organizations maintain strategic buffers positioned to maximize responsiveness while minimizing carrying costs.

Advanced inventory optimization tools employ multi-echelon models that consider the entire network simultaneously, determining optimal stock levels at each location based on service level requirements, lead times, and cost structures. These sophisticated approaches achieve better service levels with less total inventory than traditional methods by positioning stock strategically rather than uniformly across all locations.

Flexible Manufacturing and Postponement Strategies

Manufacturing flexibility enables organizations to respond quickly to demand changes, supply disruptions, or market opportunities without extensive lead times or costs. This flexibility manifests in multiple forms—equipment that can produce multiple products, workers cross-trained in various operations, and modular designs that enable late-stage customization.

Postponement strategies delay final product configuration until customer orders are received, maintaining inventory in generic or semi-finished forms that can serve multiple end products. This approach reduces forecast risk while maintaining responsiveness and reducing total inventory investment. Fashion retailers increasingly use postponement, importing undyed garments and applying colors based on regional preferences after observing early sales trends.

🚀 Leveraging Data Analytics for Competitive Advantage

Data represents the most valuable asset for modern supply chain management, but raw data alone provides little value. Organizations must develop sophisticated analytics capabilities that transform data into actionable insights driving better decisions and outcomes.

Predictive Analytics and Forecasting

Advanced forecasting techniques combine traditional statistical methods with machine learning algorithms, external data sources, and market intelligence to generate more accurate demand predictions. These systems consider numerous factors—historical patterns, promotional activities, economic indicators, weather forecasts, social media trends, and competitive actions—synthesizing them into comprehensive demand projections.

Beyond demand forecasting, predictive analytics identify potential supply disruptions before they occur. By monitoring supplier financial health, geopolitical developments, weather patterns, and transportation network conditions, organizations can anticipate problems and implement contingency plans proactively rather than reacting after disruptions materialize.

Prescriptive Analytics and Decision Automation

While predictive analytics forecasts what might happen, prescriptive analytics recommends optimal actions based on those predictions. These advanced systems consider multiple constraints, objectives, and scenarios simultaneously, recommending decisions that optimize overall performance rather than isolated metrics.

Organizations implementing prescriptive analytics automate routine decisions—inventory replenishment, transportation routing, production scheduling—freeing human attention for strategic challenges requiring judgment and creativity. This automation increases decision consistency, speed, and quality while reducing operational costs and human error.

🌐 Navigating Global Complexity and Regulatory Challenges

Operating supply chains across multiple countries introduces substantial complexity from varying regulations, customs requirements, trade agreements, and compliance standards. Organizations must develop sophisticated capabilities to navigate this complexity while maintaining efficiency and compliance.

Trade Compliance and Customs Management

International trade regulations continue evolving, with changing tariffs, trade agreements, and compliance requirements affecting supply chain design and operations. Successful organizations maintain current knowledge of relevant regulations, implement robust compliance processes, and leverage trade programs—free trade agreements, foreign trade zones, duty drawback—to minimize costs and delays.

Technology plays a crucial role in compliance management, with specialized software automating classification, documentation, and reporting requirements. These systems ensure consistent application of complex rules while maintaining audit trails demonstrating compliance to regulatory authorities.

Sustainability and Social Responsibility

Supply chain sustainability has evolved from optional corporate social responsibility to essential business practice driven by regulatory requirements, customer expectations, and investor pressure. Organizations must reduce environmental impact while ensuring ethical labor practices throughout multi-tier supply networks extending into regions with varying standards and enforcement.

Leading companies implement comprehensive sustainability programs encompassing carbon footprint reduction, circular economy principles, responsible sourcing, and supply chain transparency. These initiatives often generate cost savings through waste reduction and efficiency improvements while enhancing brand reputation and reducing regulatory risk.

💡 Building Organizational Capabilities for Supply Chain Excellence

Technology and processes alone cannot create unstoppable supply chains without the people and organizational capabilities to leverage them effectively. Companies must develop talent, foster appropriate cultures, and establish governance structures supporting supply chain excellence.

Talent Development and Cross-Functional Collaboration

Modern supply chain management requires diverse skills—analytical capabilities, technology proficiency, business acumen, relationship management, and strategic thinking. Organizations compete intensely for talent possessing these combinations, making talent development and retention critical success factors.

Successful companies invest in comprehensive training programs, provide career development opportunities, and create work environments attracting top talent. They also recognize that effective supply chain management requires cross-functional collaboration, breaking down silos between procurement, operations, logistics, sales, and finance to optimize overall performance rather than functional metrics.

Continuous Improvement Culture

Organizations achieving sustained supply chain excellence cultivate cultures embracing continuous improvement where all employees actively identify and solve problems. These cultures encourage experimentation, accept appropriate risks, and learn from both successes and failures without blame or punishment for honest mistakes.

Structured improvement methodologies—Lean, Six Sigma, Kaizen—provide frameworks and tools for systematic problem-solving. However, methodology alone proves insufficient without genuine leadership commitment and organizational support for improvement activities. Companies embedding improvement into daily work rather than treating it as separate initiatives achieve the most substantial and sustainable results.

⚡ Implementing Change: From Strategy to Execution

Developing strategies for resilient, efficient supply chains represents only the first step. Successful implementation requires careful planning, stakeholder engagement, change management, and persistent execution despite inevitable obstacles and setbacks.

Phased Implementation Approach

Large-scale supply chain transformations overwhelm organizations attempting everything simultaneously. Successful implementations adopt phased approaches that prioritize initiatives based on impact, feasibility, and dependencies. Early phases focus on foundational capabilities—data infrastructure, process standardization, governance structures—enabling subsequent initiatives.

Quick wins demonstrating tangible benefits build momentum and stakeholder support for longer-term initiatives requiring sustained investment and patience. Organizations balance quick wins with strategic projects addressing fundamental limitations and positioning for long-term competitive advantage.

Measuring Progress and Impact

Effective measurement systems track both leading indicators predicting future performance and lagging indicators confirming results. Organizations establish balanced scorecards incorporating multiple dimensions—financial performance, operational efficiency, customer satisfaction, resilience metrics, and sustainability indicators.

Beyond traditional metrics, companies measure capabilities difficult to quantify but critical for success—organizational agility, supplier relationship quality, innovation velocity, and employee engagement. These qualitative assessments provide important context for interpreting quantitative metrics and identifying improvement opportunities.

🎯 Positioning for Future Supply Chain Success

The journey toward unstoppable supply chains never truly completes. As technologies evolve, markets shift, and new challenges emerge, organizations must continuously adapt and improve. However, companies implementing the strategies outlined here—diversification, digital transformation, collaborative partnerships, intelligent efficiency, advanced analytics, global capabilities, and strong organizational foundations—position themselves to thrive regardless of future uncertainties.

Supply chain excellence increasingly differentiates market leaders from followers. Organizations treating supply chains as strategic assets rather than operational necessities gain competitive advantages difficult for rivals to replicate. They serve customers more reliably, respond to opportunities more quickly, manage costs more effectively, and navigate disruptions more successfully than competitors relying on outdated approaches.

The investment required to build truly resilient, efficient, globally successful supply chains appears substantial. However, the cost of vulnerability—lost sales, damaged reputation, eroded margins, and competitive disadvantage—far exceeds transformation investments. Forward-thinking leaders recognize this calculus and commit resources necessary to build supply chain capabilities delivering sustained competitive advantage in an increasingly complex and volatile world.

Success requires persistent effort, substantial investment, cultural transformation, and leadership commitment sustained through inevitable challenges and setbacks. Organizations embracing this journey with realistic expectations and unwavering determination will emerge stronger, more competitive, and better positioned for whatever challenges and opportunities the future presents. The question facing business leaders today is not whether to pursue supply chain excellence, but how quickly and effectively they can implement necessary changes before competitive or disruptive pressures force reactive rather than proactive transformation.

Toni Santos is a systems analyst and resilience strategist specializing in the study of dual-production architectures, decentralized logistics networks, and the strategic frameworks embedded in supply continuity planning. Through an interdisciplinary and risk-focused lens, Toni investigates how organizations encode redundancy, agility, and resilience into operational systems — across sectors, geographies, and critical infrastructures. His work is grounded in a fascination with supply chains not only as networks, but as carriers of strategic depth. From dual-production system design to logistics decentralization and strategic stockpile modeling, Toni uncovers the structural and operational tools through which organizations safeguard their capacity against disruption and volatility. With a background in operations research and vulnerability assessment, Toni blends quantitative analysis with strategic planning to reveal how resilience frameworks shape continuity, preserve capability, and encode adaptive capacity. As the creative mind behind pyrinexx, Toni curates system architectures, resilience case studies, and vulnerability analyses that revive the deep operational ties between redundancy, foresight, and strategic preparedness. His work is a tribute to: The operational resilience of Dual-Production System Frameworks The distributed agility of Logistics Decentralization Models The foresight embedded in Strategic Stockpiling Analysis The layered strategic logic of Vulnerability Mitigation Frameworks Whether you're a supply chain strategist, resilience researcher, or curious architect of operational continuity, Toni invites you to explore the hidden foundations of system resilience — one node, one pathway, one safeguard at a time.