Modern supply chains face unprecedented challenges that demand intelligent, flexible solutions capable of responding to disruption in real-time while maintaining operational excellence.

The traditional linear supply chain model—where products move predictably from manufacturer to consumer—has become obsolete in today’s volatile business environment. Companies now recognize that survival and competitive advantage depend on their ability to adapt quickly to market fluctuations, geopolitical tensions, natural disasters, and rapidly changing consumer expectations. This paradigm shift has given birth to adaptive logistics networks that leverage cutting-edge technology, data analytics, and collaborative ecosystems to create supply chains that are not just efficient, but genuinely intelligent.

Adaptive logistics networks represent a fundamental reimagining of how goods, information, and resources flow through the global economy. Unlike rigid systems that follow predetermined paths, these networks continuously learn, adjust, and optimize themselves based on real-world conditions. They combine artificial intelligence, Internet of Things sensors, blockchain technology, and advanced analytics to create self-correcting systems that anticipate problems before they occur and implement solutions autonomously.

🔄 Understanding the Adaptive Logistics Revolution

The concept of adaptive logistics networks emerged from the recognition that complexity and uncertainty are permanent features of modern commerce rather than temporary obstacles to overcome. Traditional supply chain management focused on optimization under stable conditions, but today’s reality demands systems that perform well under constant change.

Adaptive networks operate on principles borrowed from natural systems—particularly the human immune system and neural networks—that have evolved to handle uncertainty. These systems don’t just react to disruptions; they anticipate potential issues, maintain multiple contingency plans simultaneously, and learn from every interaction to improve future performance.

The foundation of adaptive logistics rests on three core capabilities: sensing, deciding, and acting. Advanced sensor networks continuously monitor conditions throughout the supply chain, from warehouse temperatures to traffic patterns to social media sentiment. Artificial intelligence systems process this information in real-time, identifying patterns and anomalies that human operators might miss. Automated execution systems then implement decisions at machine speed, adjusting routes, reordering inventory, or reallocating resources without requiring human intervention for routine decisions.

The Technology Stack Powering Adaptation

Several technological innovations have converged to make truly adaptive logistics networks possible. Cloud computing provides the computational infrastructure to process massive data streams from thousands of sources simultaneously. Edge computing brings processing power directly to warehouses, vehicles, and distribution centers, enabling split-second decisions without latency.

Machine learning algorithms continuously analyze historical patterns and current conditions to predict future demand with increasing accuracy. These systems identify subtle correlations that traditional statistical methods miss, such as how weather patterns in one region might affect purchasing behavior in another, or how social media trends predict product demand weeks before traditional indicators would register the shift.

Digital twins—virtual replicas of physical supply chains—allow companies to simulate countless scenarios and test strategies without risking real operations. When a potential disruption emerges, algorithms can run thousands of simulations in minutes to identify the optimal response strategy before implementing changes in the physical world.

📊 Building Resilience Through Network Architecture

The architecture of adaptive logistics networks fundamentally differs from traditional supply chains. Instead of linear pathways with minimal redundancy, adaptive networks embrace mesh topologies where multiple pathways connect every node. This redundancy, once considered wasteful, now provides the flexibility necessary to route around disruptions seamlessly.

Network resilience stems from diversification across multiple dimensions. Geographic diversification spreads facilities and suppliers across regions to reduce exposure to localized disruptions. Supplier diversification ensures that no single source failure can halt operations. Mode diversification allows shipments to shift between air, ocean, rail, and road transport based on current conditions rather than predetermined contracts.

Dynamic inventory positioning represents another crucial resilience strategy. Rather than storing inventory at fixed locations, adaptive networks continuously reposition stock based on predicted demand patterns, potential disruptions, and cost optimization. Products flow toward regions where they’re likely to be needed before actual orders arrive, dramatically reducing delivery times while maintaining lean inventory levels overall.

The Role of Collaborative Ecosystems

No single company can build a truly adaptive network in isolation. The most effective systems emerge from collaborative ecosystems where competitors, suppliers, logistics providers, and even customers share information and resources to mutual benefit. These ecosystems rely on carefully designed governance structures and data-sharing protocols that protect competitive information while enabling the coordination necessary for collective resilience.

Blockchain technology has emerged as a key enabler of these collaborative networks by providing transparent, tamper-proof records that all parties can trust without requiring a central authority. Smart contracts automatically execute agreements when predefined conditions are met, enabling complex multi-party transactions to occur with minimal friction and overhead.

⚡ Speed and Efficiency Gains from Adaptive Systems

While resilience often captures headlines, adaptive logistics networks deliver equally impressive improvements in speed and efficiency. By continuously optimizing operations based on current conditions rather than static plans, these systems squeeze waste from every process while accelerating throughput.

Route optimization illustrates this principle beautifully. Traditional logistics planning creates delivery routes hours or days in advance based on predicted conditions. Adaptive systems continuously recalculate optimal routes based on real-time traffic, weather, vehicle condition, and even individual driver performance characteristics. The result is measurable reductions in fuel consumption, delivery times, and vehicle wear while improving on-time performance.

Warehouse operations benefit similarly from adaptive approaches. Computer vision systems track inventory location and condition continuously, eliminating time-consuming manual cycle counts. Robotic systems adapt their picking strategies based on order patterns, physically reorganizing inventory overnight to position frequently ordered items closer to packing stations. Predictive maintenance systems monitor equipment conditions and schedule repairs during naturally occurring lulls in activity rather than during fixed maintenance windows that might interrupt peak operations.

Demand Sensing and Predictive Analytics

Perhaps the most transformative capability of adaptive logistics networks is their ability to sense and respond to demand shifts far earlier than traditional systems. By analyzing diverse data sources—point-of-sale systems, weather forecasts, economic indicators, social media trends, and even satellite imagery—these systems detect emerging demand patterns weeks before they appear in traditional ordering data.

This foresight enables proactive rather than reactive supply chain management. Production schedules adjust before inventory depletes. Transportation capacity reserves before prices spike. Product assortments shift before consumer preferences fully transition. The cumulative effect is a supply chain that seems almost prescient, consistently delivering what customers want, when they want it, without carrying excessive inventory or capacity.

🌍 Sustainability Through Intelligent Resource Management

Adaptive logistics networks offer surprising sustainability benefits by eliminating waste through intelligent resource utilization. Every empty mile driven, every warehouse operating below capacity, and every product that becomes obsolete before sale represents environmental damage as well as economic loss. Adaptive systems address all these inefficiencies simultaneously.

Transportation optimization reduces carbon emissions not just through better routing but through improved load consolidation. Adaptive networks identify opportunities to combine shipments from multiple sources or to multiple destinations, maximizing vehicle utilization. Dynamic pricing mechanisms encourage shippers to provide flexible delivery windows, allowing further consolidation opportunities.

Circular economy principles integrate naturally into adaptive logistics networks. Systems track products throughout their lifecycle, identifying opportunities for repair, refurbishment, or recycling. Reverse logistics flows seamlessly integrate with forward flows, with the same vehicles and facilities handling both directions efficiently. Materials recover value through multiple lifecycle passes rather than ending in landfills after single use.

Energy Management and Carbon Optimization

Advanced energy management represents another sustainability dimension where adaptive networks excel. Warehouses coordinate energy consumption with grid conditions, running energy-intensive processes when renewable energy is abundant and electricity prices are low. Electric vehicle charging schedules optimize around similar factors while ensuring vehicles are ready when needed.

Some adaptive networks now incorporate carbon emissions as an optimization variable alongside traditional metrics like cost and speed. Customers can choose delivery options based on carbon footprint, and systems automatically select lower-emission alternatives when other factors are equal. This capability transforms sustainability from an abstract corporate commitment into a concrete operational reality embedded in daily decisions.

🛠️ Implementation Strategies for Adaptive Transformation

Transforming traditional supply chains into adaptive logistics networks represents a significant undertaking that most organizations approach incrementally rather than through wholesale replacement. Successful implementations typically follow a maturity model that builds capability progressively while delivering value at each stage.

The journey often begins with visibility—implementing sensors, tracking systems, and data integration platforms that provide real-time insight into supply chain operations. Many organizations discover that simply seeing what’s happening across their networks reveals optimization opportunities that justify the technology investment before any advanced analytics deploy.

The second stage typically involves predictive analytics that forecast future conditions based on historical patterns and current trends. These capabilities enable better planning even before systems gain the ability to respond automatically to changing conditions. Organizations develop confidence in algorithmic recommendations by testing them against human judgment in low-risk scenarios before granting systems autonomous decision authority.

Organizational Change Management

Technology represents only one dimension of adaptive transformation. Equally important are organizational and cultural changes that enable people to work effectively with intelligent systems. Supply chain professionals must evolve from executing predefined plans to managing systems that generate and execute plans autonomously. This transition requires new skills, different performance metrics, and revised decision-making processes.

Successful organizations invest heavily in training and change management, helping teams understand not just how to operate new systems but why adaptive approaches create value. They redesign roles to focus on activities where human judgment adds unique value—handling edge cases, building relationships, developing strategy—while delegating routine decisions to algorithms. Performance metrics shift from measuring adherence to plans toward measuring outcomes like customer satisfaction, cost efficiency, and resilience.

💡 Real-World Success Stories and Measurable Outcomes

Companies across industries have demonstrated the tangible benefits of adaptive logistics networks through impressive performance improvements. Leading retailers have reduced inventory levels by 20-30% while simultaneously improving in-stock rates, a seeming contradiction that adaptive demand sensing makes possible. Fast delivery times have shortened by days or even weeks as systems position inventory predictively rather than reactively.

Manufacturing organizations report similar gains. Production schedules adapt to supply availability and demand forecasts in real-time, reducing both stockouts and excess inventory. Transportation costs decline by double-digit percentages as systems identify consolidation opportunities and optimize mode selection continuously. Quality improves as sensors detect potential issues early and systems automatically adjust processes or route products for additional inspection.

Perhaps most impressive are the resilience gains demonstrated during actual disruptions. When the pandemic, natural disasters, or geopolitical events disrupt traditional supply chains catastrophically, adaptive networks route around problems with minimal customer impact. Companies with mature adaptive capabilities maintained service levels that their competitors simply couldn’t match, gaining market share that persisted long after specific disruptions resolved.

🔮 The Future Landscape of Adaptive Logistics

Adaptive logistics networks continue evolving rapidly as new technologies mature and organizations gain experience with intelligent systems. Several trends will shape the next generation of capabilities, pushing adaptive systems toward ever-greater autonomy and sophistication.

Autonomous vehicles—both ground-based and aerial—will dramatically expand the operational possibilities for adaptive networks. These systems will enable 24/7 operations with routing flexibility impossible for human-driven fleets. Small autonomous vehicles might make multiple daily deliveries to individual households, while large autonomous trucks operate continuous relay systems that never stop moving.

Artificial intelligence capabilities continue advancing at remarkable pace. Next-generation systems will understand natural language, enabling verbal interaction with logistics networks as easily as with human assistants. Computer vision will identify product damage, quality issues, or handling errors automatically. Reinforcement learning algorithms will discover optimization strategies that human designers never imagined by exploring vast solution spaces through simulated experimentation.

Hyperconnected Supply Chain Ecosystems

The future envisions supply chains as hyperconnected ecosystems where boundaries between companies blur through deep integration and automated collaboration. Products might carry digital identities that track their journey from raw materials through manufacturing, distribution, use, and eventual recycling. These intelligent products would communicate their status, location, and needs continuously, enabling unprecedented visibility and control.

Standards development and regulatory frameworks will play crucial roles in realizing this vision. Industry consortiums are developing protocols for secure data sharing, interoperable identification systems, and governance models for collaborative networks. Governments are establishing regulations that encourage innovation while protecting consumer interests, data privacy, and competitive markets.

🎯 Strategic Imperatives for Supply Chain Leaders

Supply chain executives face urgent decisions about how and when to embrace adaptive logistics networks. While the benefits are clear, the path forward requires careful strategic thinking and substantial investment. Several imperatives should guide this journey.

First, organizations must assess their current maturity honestly and establish realistic transformation roadmaps. Few companies can leap directly to fully adaptive operations; most require phased approaches that build capabilities progressively while delivering incremental value. Understanding where to start and which capabilities to prioritize requires clear-eyed analysis of current strengths, weaknesses, and strategic priorities.

Second, technology partnerships become increasingly important as supply chains grow more sophisticated. No single vendor provides all necessary capabilities, and integrating diverse systems requires careful architecture and governance. Companies must decide which capabilities to build internally versus acquire through vendors versus access through ecosystem partnerships.

Third, talent strategy requires immediate attention. The skills needed to design, operate, and improve adaptive logistics networks differ substantially from traditional supply chain management. Organizations must recruit new talent while retraining existing teams, creating career paths that attract and retain the data scientists, software engineers, and systems thinkers who will drive future success.

Finally, leaders must cultivate organizational cultures that embrace experimentation and learning. Adaptive systems improve through continuous iteration, which requires accepting that not every experiment will succeed. Organizations that punish failure or demand perfection will struggle to innovate at the pace required for competitive advantage.

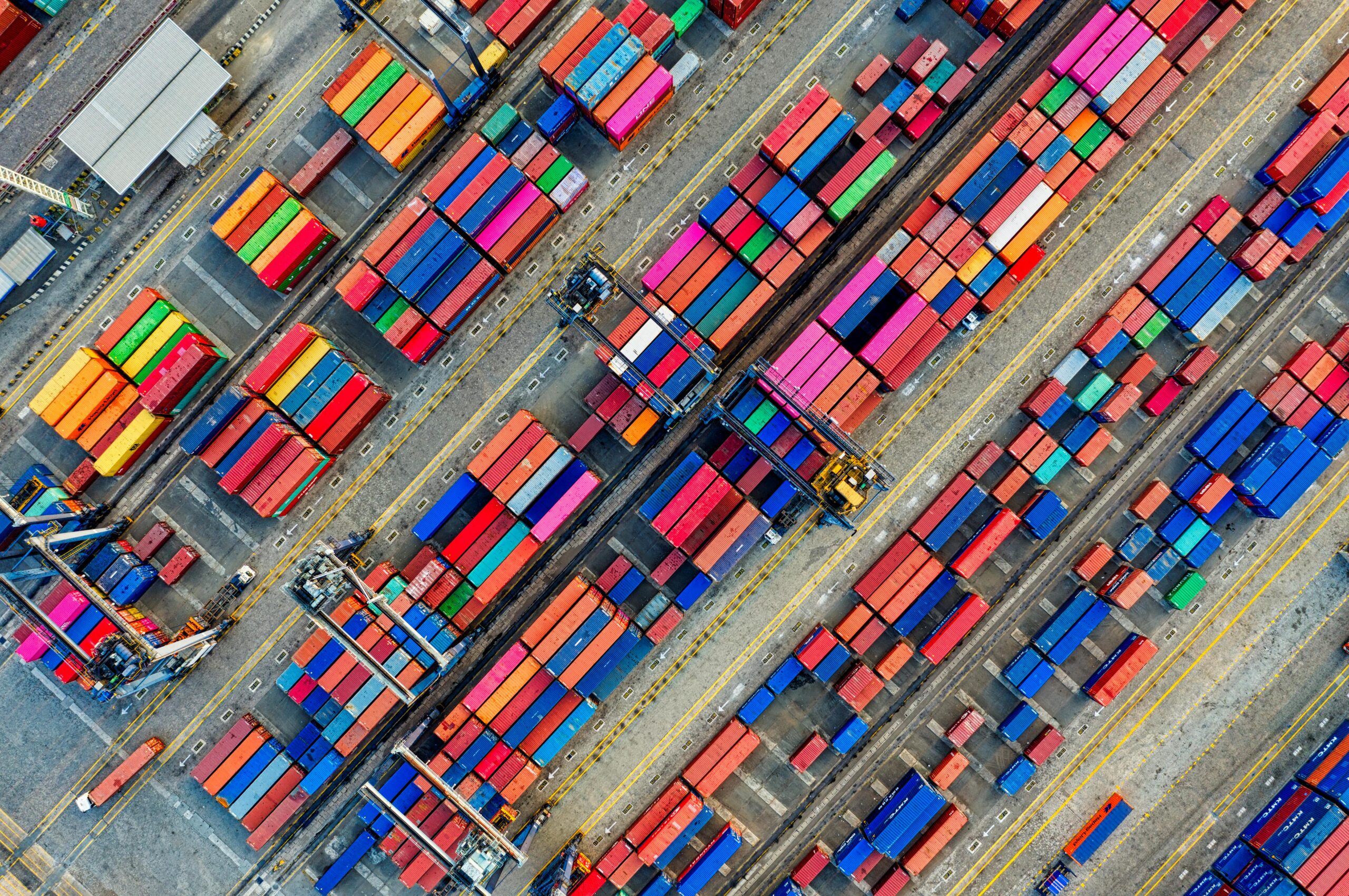

The transformation toward adaptive logistics networks represents one of the most significant shifts in supply chain management since the introduction of containerization revolutionized global trade. Companies that embrace this change thoughtfully will gain sustainable competitive advantages through superior resilience, efficiency, and customer responsiveness. Those that cling to traditional approaches will find themselves increasingly unable to compete as adaptive networks become the industry standard. The revolution is underway, and the time for strategic action is now. 🚀

Toni Santos is a systems analyst and resilience strategist specializing in the study of dual-production architectures, decentralized logistics networks, and the strategic frameworks embedded in supply continuity planning. Through an interdisciplinary and risk-focused lens, Toni investigates how organizations encode redundancy, agility, and resilience into operational systems — across sectors, geographies, and critical infrastructures. His work is grounded in a fascination with supply chains not only as networks, but as carriers of strategic depth. From dual-production system design to logistics decentralization and strategic stockpile modeling, Toni uncovers the structural and operational tools through which organizations safeguard their capacity against disruption and volatility. With a background in operations research and vulnerability assessment, Toni blends quantitative analysis with strategic planning to reveal how resilience frameworks shape continuity, preserve capability, and encode adaptive capacity. As the creative mind behind pyrinexx, Toni curates system architectures, resilience case studies, and vulnerability analyses that revive the deep operational ties between redundancy, foresight, and strategic preparedness. His work is a tribute to: The operational resilience of Dual-Production System Frameworks The distributed agility of Logistics Decentralization Models The foresight embedded in Strategic Stockpiling Analysis The layered strategic logic of Vulnerability Mitigation Frameworks Whether you're a supply chain strategist, resilience researcher, or curious architect of operational continuity, Toni invites you to explore the hidden foundations of system resilience — one node, one pathway, one safeguard at a time.